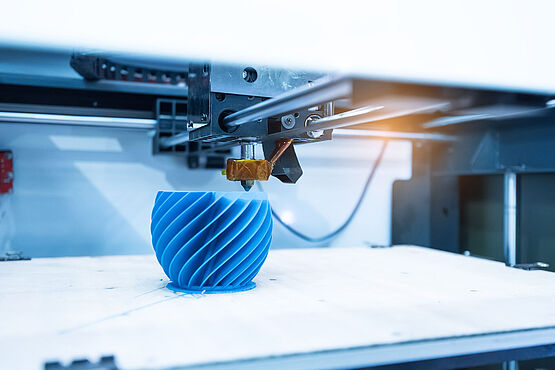

Additive manufacturing: emissions from 3D printers

Whether used for tool and machine parts, packaging or everyday items – 3D printers are now virtually indispensable. Despite the obvious advantages such as cost efficiency and speed, the new technology also raises the question of emissions caused by ultra-fine particles and volatile organic compounds.

These occur when handling the devices or during 3D printing with plastics and metals. To obtain certainty about the emissions, the WESSLING experts offer indoor air measurement and occupational health and safety consulting. This includes setting up suitable work areas for 3D printing.

Our services in the field of additive manufacturing

Our services in the field of additive manufacturing

Emission of airborne particles and VOC

Emission of airborne particles and VOC

Professional additive manufacturing processes involving metals primarily take place in encapsulated devices. However, these devices have to be opened for maintenance or loading. This can lead to the release of particles and volatile organic compounds (VOCs), which can be damaging to health. To complicate matters, each fibre behaves differently on different printers.

As additive procedures are also increasingly being used in the field of food production – for packaging, for instance – food safety has to be observed according to the German legislation. WESSLING determines the fine dust emissions of devices, and analyses the (food) safety of products and the effectiveness of filter systems.

Ihr Kontakt zum Thema Additive manufacturing

Wir unterstützen Sie gern.

- André Schmitz

- +49 2505 89-673

- andre.schmitz@wessling-ce.de

Our range of services in additive manufacturing

- Emission of airborne particles and VOC

- Physical-chemical characterisation of products made of plastics and metal: harmful substances, chemical resistance, technical cleanliness, etc.

- Analysis of product food safety

- Check of the effectiveness of filter systems; certification if necessary

- Advice on occupational health and safety and the set-up of suitable 3D printing work areas

- Explosion protection on use of powders

- REACH and RoHs conformity

Your contact for the topic of additive manufacturing

We will be happy to support you.

- André Schmitz

- +49 2505 89-673

- andre.schmitz@wessling-ce.de